We develop and implement own technologies of chemical and physical production of flat glass.

PRODUCT PORTFOLIO

DAGLASS is a globally operating company that has been successfully processing the flat glass. Using its unique technological know-how, which has been constantly evolving for the needs of ever-changing market needs, DAGLASS manufactures and processes the most technologically advanced glass. Our products are unique on the market and improves the quality of life around the world. Thanks to a rich product portfolio, everyone can find a perfect solution for himself.

DAGLASS NANO-BARREN™ ANTISEPTIC GLASS

It is produced with the use of magnetron technology and has biostatic properties. The NANO-BARREN ™ coating kills microorganisms with 99.999% efficiency.

DAGLASS DIAMOND GLASS

Hydrophobic glass with the highest resistance to scratching and corrosion. It is a great choice for partitions, partition walls, and shower cabinets.

ANTI-REFLECTIVE GLASS

As we change the surface morphology, our glass increases the light transmittance. Consequently, it improves the efficiency of lightning and significantly advances the quality of image on screens.

DIFFUSED GLASS

It scatters the light in a controlled and steady manner. Therefore, it removes shadows and gives more transparency in contact with water. It is a perfect solution for lightning and greenhouse sector.

NON-GLARE GLASS

Anti-glare glass with changed morphology in the nano scale. It is suitable for LED screens and LCD screens. The anti-finger print feature makes it an ideal solution for touch screens. It reduces light reflexes and improves the image.

DAGLASS MAGNETRON GLASS

The magnetron technology improves the properties of glass – its physical, optical, mechanical properties and resistance to many chemical factors.

DAGLASS THERMALLY TEMPERED & LAMINATED GLASS

Thermally tempered glass is a safety glass – in case of damage breaks into small pieces without sharp edges. The foil between the panes of glass improves durability, ensures stability in case of breaks and prevents the glass from falling out of the structure.

DAGLASS DOUBLE GLAZED GLASS

Double glazed glass consist of 2, 3 or 4 glass panes, separated by a spacer, and at the same time permanently connected with each other by means of a seal. Double glazed glass can protect against heat loss, noise and against excessive heating.

DAGLASS MAGNETRON MIRRORS

DAGLASS mirrors are produced with the use of magnetron sputtering. As the metallic coating is covered by special paints, DAGLASS mirrors are protected against possible mechanical damages.

As there is a possibility of choosing different shades, mirrors have a wide range of applications for any interior design.

DAGLASS COLOURED/PRINTED GLASS

The method of screen printing with ceramic paint gives high print quality and high mechanical resistance to weather conditions. At the same time providing flexibility in terms of patterns and colour palette.

A highly effective painting robot provides quick and smooth coating using resin, water, or ceramic paints.

DAGLASS BODY-TINTED GLASS

Body-tinted glass is mainly used as an element of interior design, as it has aesthetic value. Body-tinted glass reduces the amount of light and suppresses solar radiation, so it can be used in places where we want to protect against excessive sunlight.

DAGLASS MATT GLASS

DAGLASS matt glass is produced by etching process. Used as a decorative element in interior arrangements due to its neutral and matt appearance, medium light transmittance and total blurring of the image behind the glass.

Company profile

DAGLASS is an international company specializing in glass production, operating for over 35 years in the market. Valuable and wide experience in glass processing has been gained through implementation of innovative solutions and projects. The consequence of a coordinated development strategy is a wide product portfolio to meet demanding needs of various sectors of the economy.

The company is the world pioneer of innovative solutions. DAGLASS has successfully managed to create specific methods for forming the visible light beam in space and the geometry of the propagation of electromagnetic waves in the infrared and ultraviolet ranges that are invisible ones.

INDUSTRY

DAGLASS company responds to the needs of the modern economy. Thus, R&D Department that is primarly staffed by engineers and specialsists develop and implement own solutions in the following areas:

• Light Transmission

• Optics

• Chemical processes of glass processings

• Additional glass functionalities

ARCHITECTURE

All solutions are the results of research and development works carried out in the close cooperation with leading scientists, and many national and international institutions.

• Line for the anti-reflective glass production

• Magnetron sputtering line for metallic layers

• Line for chemical treatment of glass – deep etching

• Chemical glass tarnishing

CONSTRUCTION

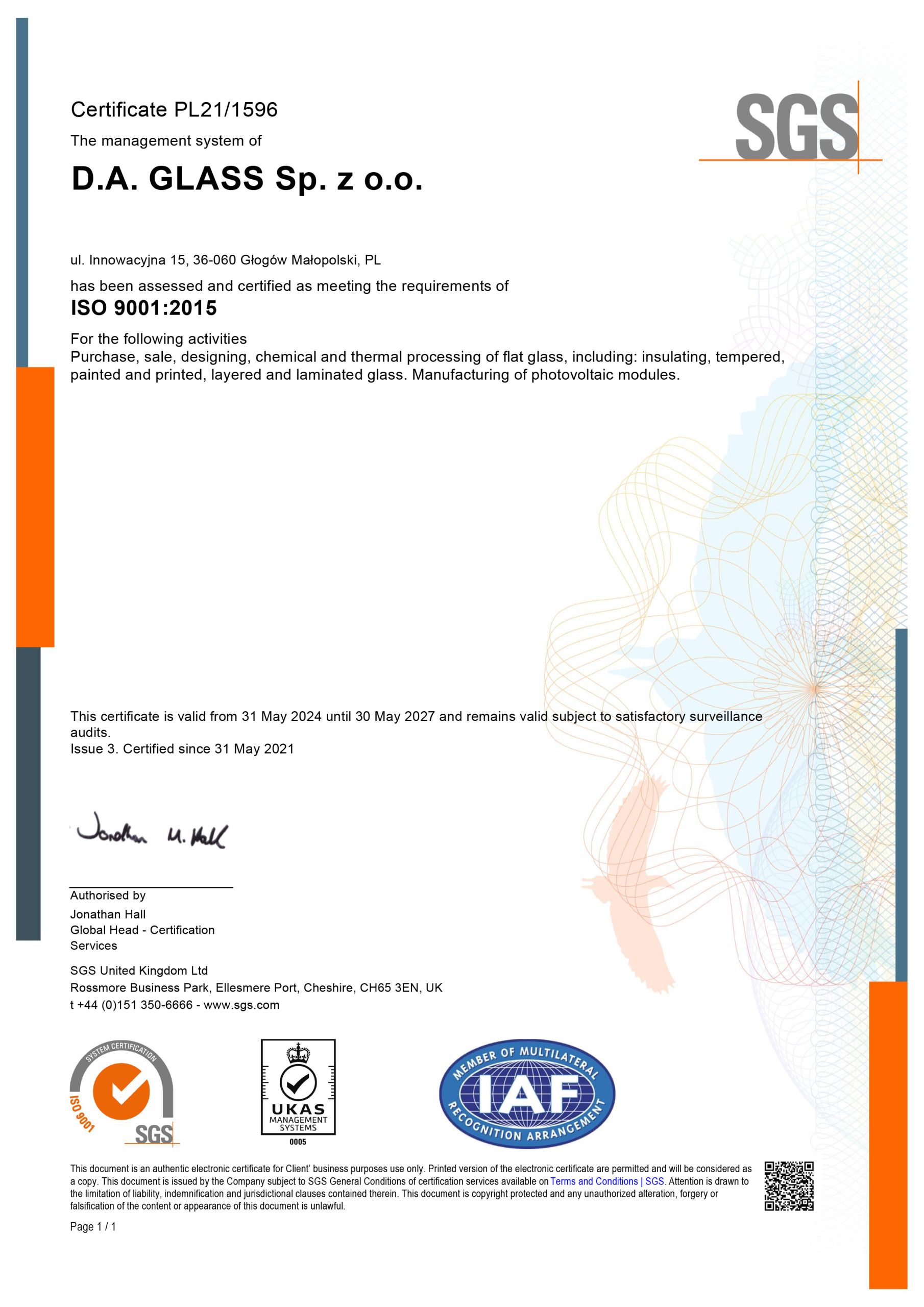

DAGLASS has the necessary certificates which confirm the compliance with the quality management standards in the enterprise. Manufacturing operations and procedures are carried out with utmost care and according to the highest standards, and therefore during chemical production of diffusion and deep-etched glass no waste is left.

The company has successfully implemented ISO 9001: 2015 quality management system.

FUTURE

DAGLASS intends to continue investments in technological development, technical expertise and product portfolio. All with the goal of promoting Polish innovative products featuring the premium quality and trust around the world.